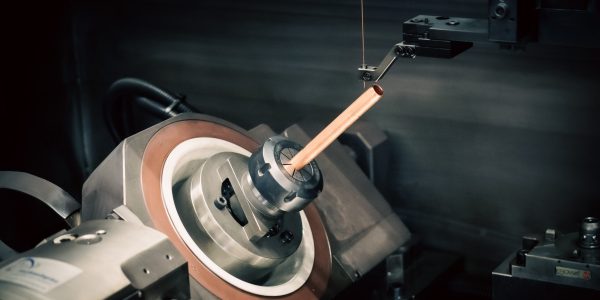

Small hole EDM drilling & Sinker EDM

Small hole EDM drilling • EDM Threading • Deep drilling • Fast hole edm drilling • High precision drilling • Hole popper

12 mm/minute

removal rate in tungsten carbide

600 %

faster in steel and tungsten carbide at diameter 0.15 mm than a conventional water based machine

40 mm/Minute

one edm machine for all applications

Start hole drilling with up to 40 mm/min

Starter holes can be eroded with minimal energy input using EDM drilling, significantly reducing heat-affected zones and minimizing the risk of failure in carbide components.

Our high-performance EDM machines deliver exceptional drilling speeds—up to 12 mm/min in tungsten carbide and 40 mm/min in steel—redefining the concept of start hole EDM drilling in precision manufacturing.

Micro-drilling from Ø 0.06 mm

All electrically conductive materials can be reliably and reproducibly machined using electrode diameters as small as 0.05 mm—ideal for ultra-precise components in high-sensitivity industries.

Micro holes below Ø 0.3 mm, where conventional methods often fail, are well within our comfort zone.

deep hole drilling with ratio 300:1

Our EDM systems are engineered for ultra-deep precision drilling, achieving length-to-diameter ratios of up to 300:1—well beyond the limits of conventional deep hole drilling machines.

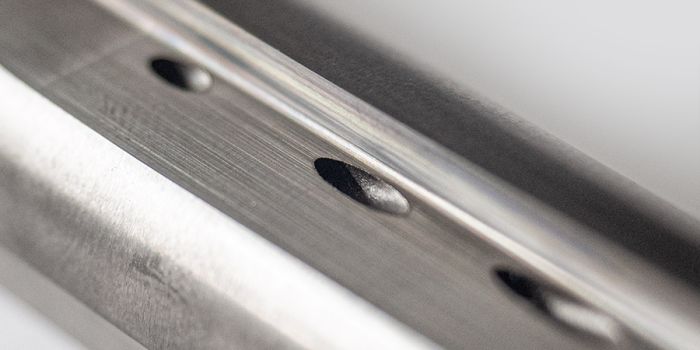

complex functional holes

Non-contact EDM drilling enables hole creation at virtually any entry angle, offering maximum design flexibility for complex geometries.

Die sinking with 50 AMPS

Our machines are also suitable for thread sinking, clearing, or embossing contours. The 50A generator and precise control technology enable removal rates comparable to those of classic sinking machines.

electrode changer and rotary unit

automation

automated electrode changer

6-, 8-, or 40-position electrode changer.

This allows complex drilling patterns to be eroded in less time, without the need for manual electrode replacement.

rotary-tilt axis

tooling without limits

The indexing head adds one or two additional axes to our drilling EDM machine.

Ideal for drilling at inclined angles.

an allroud machine for your projects

starthole and microdrilling. threading. deep drilling. AGEMA has got the right machine for you

precision. durability. innovation - we are agema germany

a family business from the black forrest

AGEMA specializes in the development and manufacturing of versatile all-in-one EDM systems. Powered by an innovative generator, our machines deliver precise drilling performance where conventional methods reach their limits. They are capable of micro drilling, start hole drilling, and functional hole machining across all axes. Additionally, the system enables die-sinking for features such as threads and fits.

Our machines are proudly “Made in Germany” and stand for the highest quality. Every AGEMA system is fully developed, designed, manufactured, and assembled in-house. With advanced automation options such as tool and workpiece changers, and a modular Windows-based control system, AGEMA EDM machines offer maximum flexibility, scalability, and long-term reliability—often lasting for decades.

custom manufacturing

A combination of contract manufacturing and mechanical engineering

we provide quality

Looking for a reliable solution for complex micro drilling or multi-axis precision machining? In our contract manufacturing division, we use the latest AGEMA machines to bring your projects to life.

With our high-precision EDM drilling systems, we set new standards in quality and reliability. The close integration of manufacturing and machine engineering allows us to continuously optimize our processes—resulting in even more durable and precise machines that prove themselves in real-world applications.

- Precise micro and multi-axis drilling according to your specifications

- Deep hole drilling with minimal heat-affected zones

- Start hole drilling of all diameters in top quality

- Reliable partnership for your manufacturing projects

we machine these materials

- Hardened tool steels and tungsten carbide

- Titanium alloys

- Heavy metals such as molybdenum and tungsten

- Conductive ceramics like silicon carbide

- Nickel-based alloys including Inconel, Hastelloy, and Nitinol

- Specialty alloys such as Kovar, Invar, and Ferrotitanit

industries and applications

diversity through technical lead

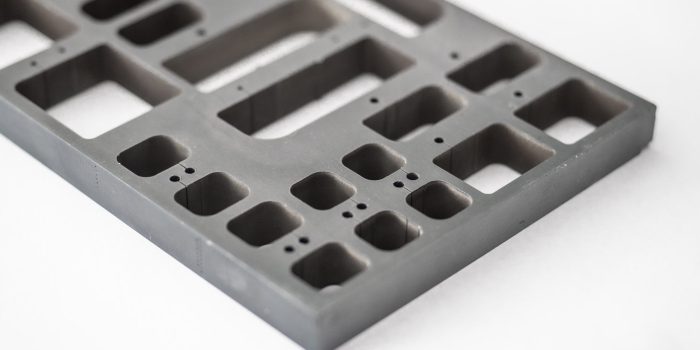

tool and mold making

In tool and mold making—where EDM drilling is traditionally known as “start hole drilling” or “hole popping”—the demand for increasingly precise and complex start holes continues to grow. Our EDM drilling and die sinking machines are ideally suited for micro drilling applications such as vent holes or cooling channels, as well as for machining threads in tungsten carbide or hardened steel with high accuracy.

Automotive

AGEMA EDM drilling systems enable high-precision machining of fuel injector holes, cooling channels, and lubrication passages. This technology helps improve fuel efficiency, increase production speed, and enhance component reliability.

aerospace

EDM drilling on AGEMA machines is used to create precise cooling holes in turbine blades, engine components, and other heat-resistant parts made from materials such as titanium or nickel-based alloys (e.g., Inconel).

medical engineering

Manufacturing of medical instruments using deep hole and micro drilling, implants (e.g., precision holes in titanium implants), and micro components such as catheters or needles.

energy industry

AGEMA machines enable precise micro drilling in fuel cells, gas turbine components, and measurement probes—optimizing energy efficiency and process monitoring. Additionally, artificial defects can be created for the calibration of testing equipment, contributing to enhanced nuclear safety.

Electronics and Semiconductor Industry

Precise micro drilling for vacuum suction units and measurement probes in wafer production. Thanks to our EDM technology and minimal energy input, AGEMA machines can process hard materials such as silicon carbide (SiC) without thermal damage—enhancing component reliability.

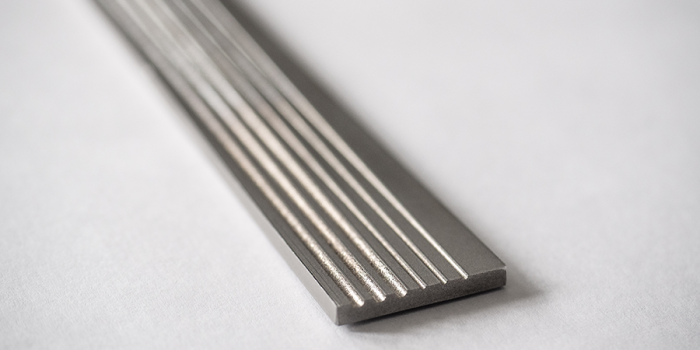

textile industry

With EDM milling, multi-axis machining, and fully automated processes, AGEMA machines enable the precise production of spin and injection nozzles as well as shot and intermediate nozzles. Compared to laser-machined nozzles, our EDM-produced nozzles offer superior performance thanks to improved surface quality and the ability to manufacture more complex geometries.

defense

Our hole-drilling EDM machine enables precise machining of all electrically conductive materials, including titanium, Inconel, Hastelloy, molybdenum, tungsten, and cobalt-based alloys. Utilizing state-of-the-art Electrical Discharge Machining (EDM) and multi-axis technology, it is ideally suited for demanding applications in the defense sector—such as the production of cooling holes, precision components for weapon systems, and complex part geometries.

jewelry and watch industry

Our high-precision machines are used to create micro-holes in materials such as gold, platinum, titanium, and conductive ceramics, meeting the highest manufacturing standards in the watchmaking and jewelry sectors.