Start hole drilling. Micro drilling. Deep hole drilling. edm threading. die-sink edm.

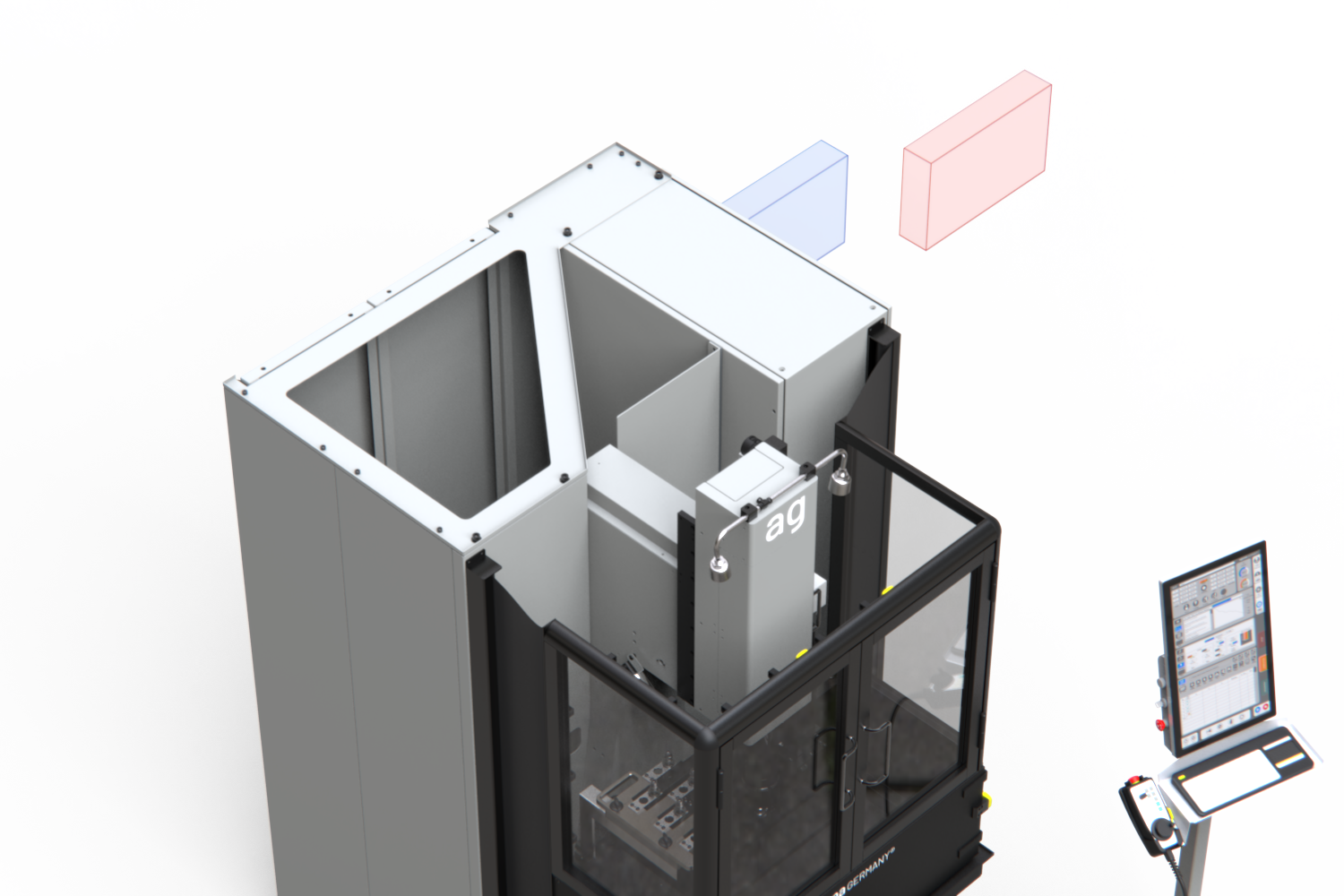

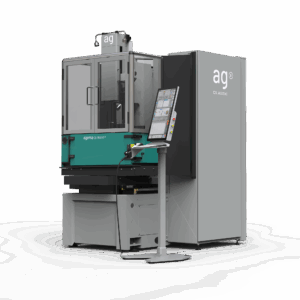

The AGEMA drilling erosion machine is available in two sizes, which primarily differ in their travel range and electrode stroke. For even greater flexibility, the AG430 can optionally be equipped with a larger electrode and guide changer. The generator, software, and operating concept are identical for both models.

a high-performance generator that meets all demands

precision and performance

The heart of our EDM drilling machine is the newly developed pulse generator. It embodies over 30 years of company expertise with state-of-the-art power electronics, setting new standards in precision, speed, and efficiency for EDM drilling.

supreme drilling performance

With up to 12 mm/min in carbide and 40 mm/min in steel, our machines stand out with above-average performance. Naturally, the proven AGEMA quality takes top priority. This means high productivity with maximum precision drilling quality – in record time.

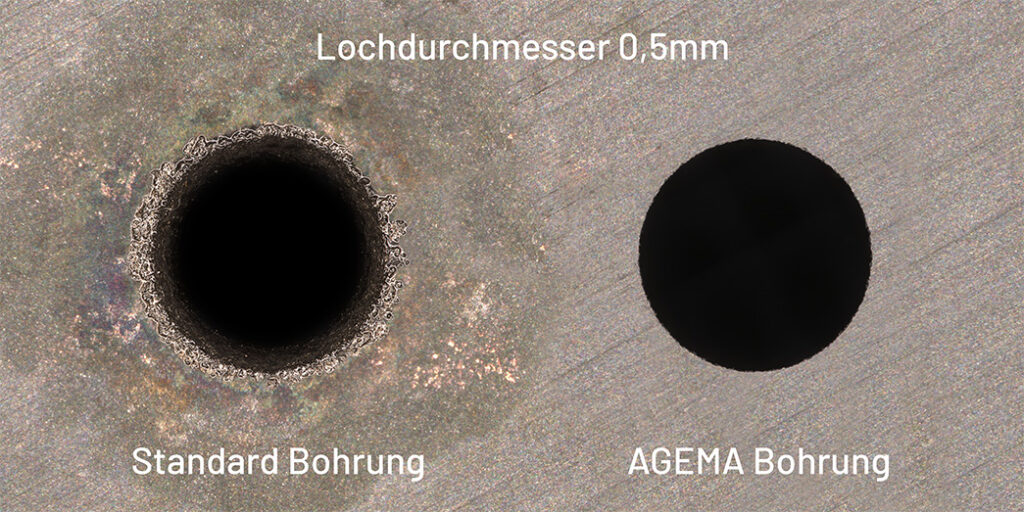

cylindrical drilling

With the innovative AGEMA generator technology, electrode wear is precisely controlled, ensuring that bores are almost perfectly cylindrical using just a single electrode.

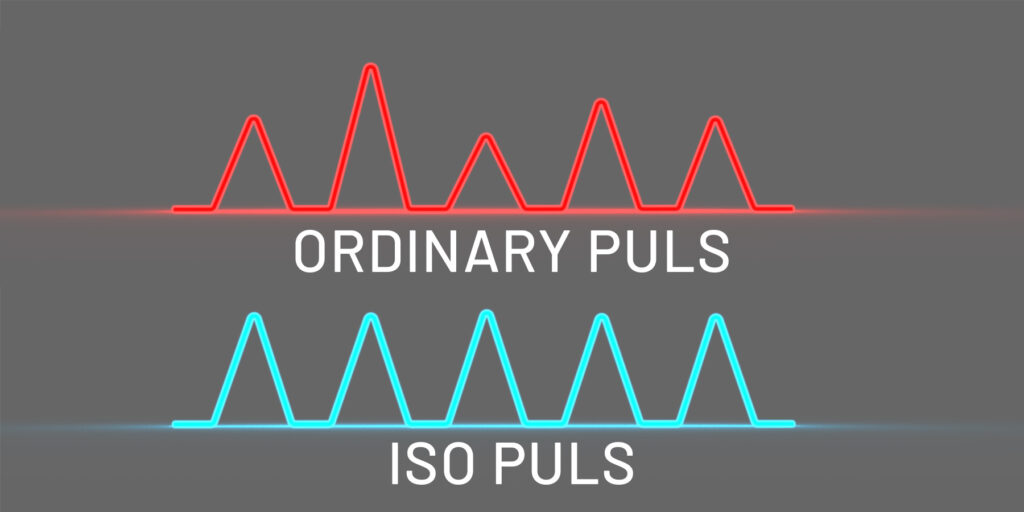

minimal electrode wear

Every single discharge is precisely controlled, ensuring that each discharge delivers the same amount of energy. This minimizes electrode wear and improves surface roughness.

outstanding surface quality

Compared to EDM machines with water-based dielectric, the gentle energy input significantly reduces microcracks and thermal damage in the bore, substantially lowering the failure probability of components.

energy efficiency

The state-of-the-art and efficient circuit design of the generator, an intelligent standby mode when not in use, and an innovative high-pressure system significantly reduce energy consumption. This substantially decreases the waste heat released into the dielectric and the environment.

Minimized Downtime

In the event of a generator failure, it can be directly replaced with a new generator on-site. This ensures minimal machine downtime, as there are no complex maintenance tasks required on the machine. In other words: you keep producing at your site, while we handle repairs at ours.

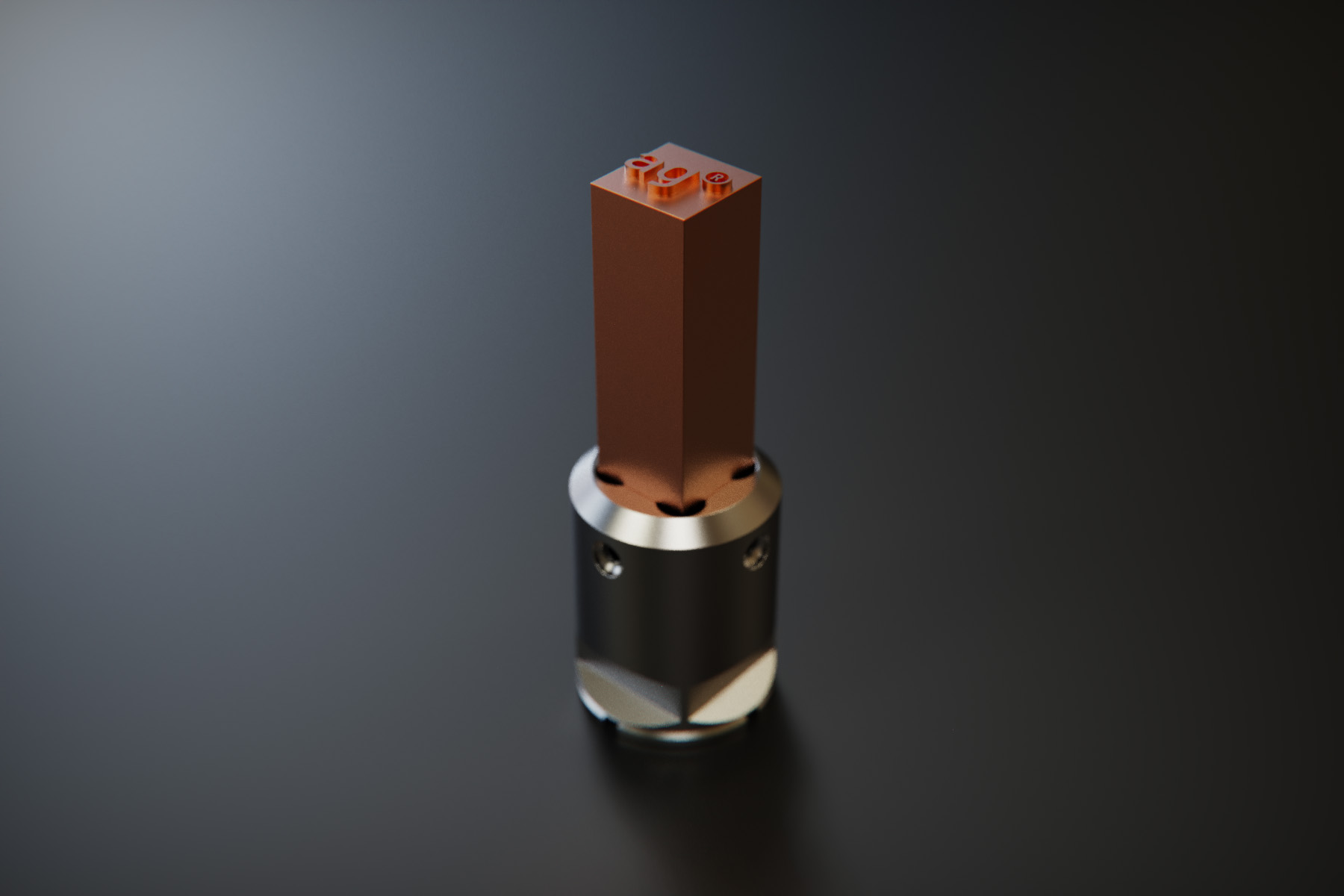

a clamping system for multiple purposes

EDM drilling and sinking

quick change system

With the new pneumatic quill, electrodes can be exchanged within seconds—either manually or automatically via an electrode changer. The zero-point clamping system uses Erowa Compact as its interface, making it ideal for both EDM drilling and EDM sinking

thread sinking

The clamping system enables rapid changes between different electrode holders, including a variant for threaded electrodes. This allows thread geometries to be sunk into extremely hard materials by radially deflecting the threaded electrode within a borehole. As a result, precise threads can be created in materials where conventional thread cutting would be impossible.

sinking micro geometries

The EDM machine is specifically optimized for hole-drilling EDM but can also be used for sinker EDM applications. Thanks to its innovative generator design, the Erowa electrode quick-change system, a manually adjustable C-axis, and versatile flushing options (standard, pulse, and suction flushing), it is also well-suited for sinker EDM tasks such as thread creation, embossing contours, and cavity machining.

automated electrode replacement

Automation of processes for lights-out manufacturing

6/8/40 electrode replacing system

Thanks to our automated electrode changer, complex drilling patterns can be eroded in less time without the need for manual electrode replacement. This increases productivity and ensures process stability by minimizing manual operations.

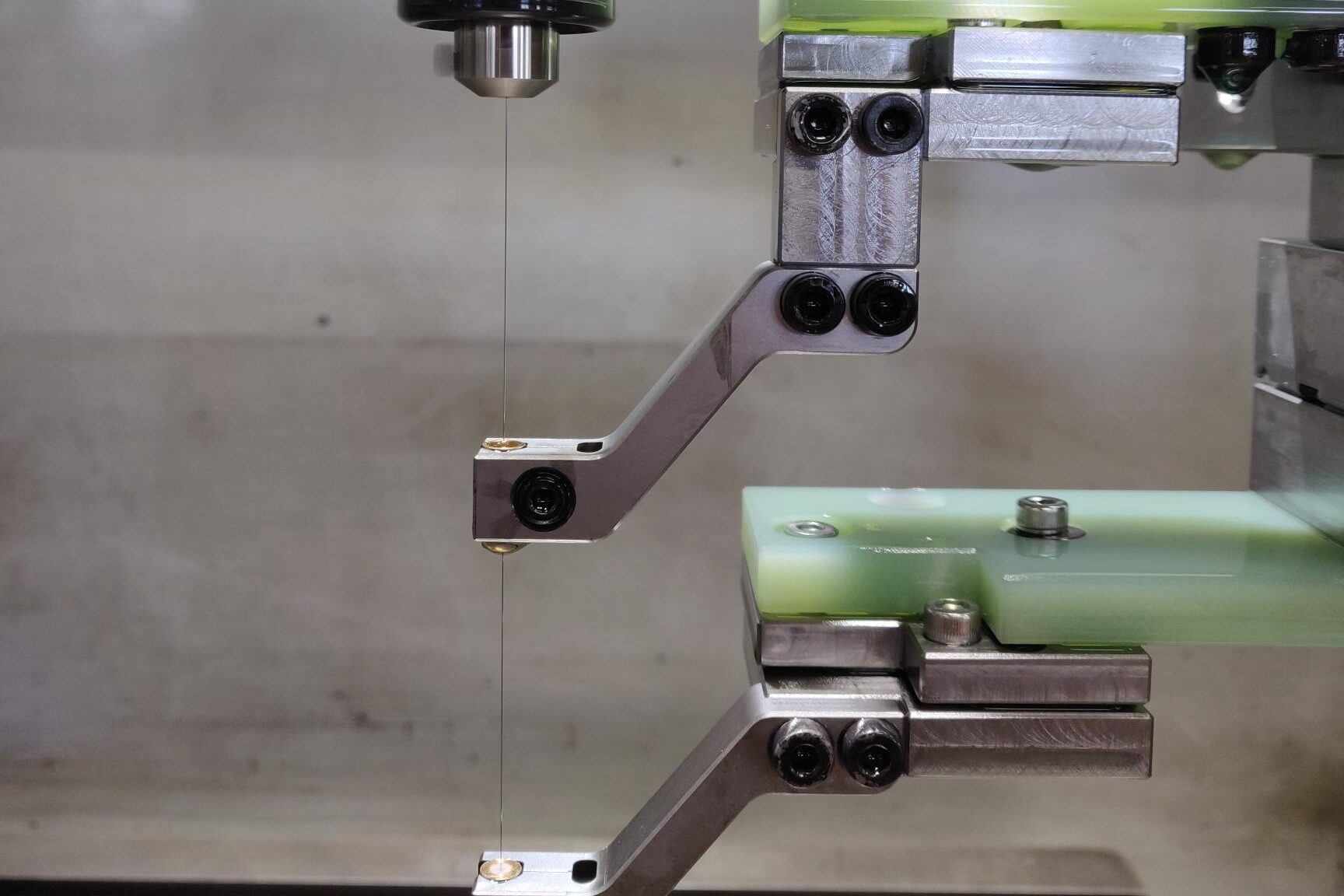

Intermediate electrode guidance for increased precision

for the drilling of holes with high aspect ratios

perfect electrode trajectory

A second guide holder is installed on its own independent axis to increase process stability, guiding precision, and thereby drilling performance—especially when drilling very deep holes.

A rotary and swivel axis for every machining angle

Full rotational and tilting motion for maximum flexibility in machining operations

5-axis machining

The indexing head expands our EDM drilling machine by one or two additional axes. Thanks to ITS’s high-precision multi-axis technology, cooling and venting holes, for example, can be precisely placed into complex part geometries at very shallow angles.

A versatile control system tailored to different user needs

Touch. Tactile. Intuitive. Interactive on all levels.

22" touch display with mouse and keyboard

The Windows-based control system impresses with its ease of use and seamless integration into company networks. Remote maintenance ensures immediate support. The completely redesigned, intuitive HMI allows for easy operation via touchscreen or, alternatively, with a mouse and keyboard—and is optimally complemented by the AGEMA handheld control device.

machine accessories

quality products for precision manufacturing

We offer a full range of accessories, tools, and spare parts for all AGEMA machines—including legacy models dating back to the last century.

all advatages at a glance

- Interchangeable high-performance generator of the latest generation

- Erowa quick-change system for fast swapping of various drilling and sinking electrodes

- Modern operating concept: 22″ touchscreen HMI, input devices, and handheld control unit

- Rotary and swivel axis for machining in every angle

- Supports a wide range of applications:

- Start hole drilling

- Micro drilling

- Deep hole drilling

- Functional hole drilling

- Sinker EDM

- Ultra-small hole capability starting from 0.06 mm

options for the ag 320 and ag 430

gamechanging addons

- Additional intermediate guide for perfect electrode guidance

- 6-, 8-, or 40-electrode changer for lights-out manufacturing

- Rotary and swivel axis unlimited machining angles

- Automation-ready with various integration options

AG 320 CLASSIC And AG 430 CLASSIC

Are you looking for a simpler machine?

Discover our Classic series—a cost-optimized drill EDM machine that is perfect for pilot hole drilling!

machine specifications

| Parameter | AG 320 | AG 320 Classic | AG 430 | AG 430 Classic |

|---|---|---|---|---|

| traverse path XY | 300 × 200 mm | 300 × 200 mm | 400 × 300 mm | 400 × 300 mm |

| electrode stroke | 280 mm | 280 mm | 400 mm | 400 mm |

| max. workpiece height | 240 mm | 240 mm | 300 mm | 300 mm |

| basin | 800 × 500 × 260 mm | 800 × 500 × 260 mm | 1050 × 650 × 320 mm | 1050 × 650 × 320 mm |

| electrode diameter | 0,05 – 10 mm | 0,2 – 10 mm | 0,05 – 10 mm | 0,2 – 10 mm |

| positioning accuracy | 0,002 mm | 0,02 mm | 0,002 mm | 0,02 mm |

| max. flushing pressure | 140 bar | 80 bar | 140 bar | 80 bar |

| max. workpiece weight | 200 kg | 200 kg | 200 kg | 200 kg |

max. electrode weight | 5 kg | 5 kg | 5 kg | 5 kg |

| machine weight | 1600 kg | 1600 kg | 1900 kg | 1900 kg |

| electrode changer | 6 fold | No | 8 / 40 fold | No |

| guide changer | No | No | Yes | No |

| generator performance | 50 A | 40 A | 50 A | 40 A |

| max. drilling performance | TC 12 mm/min Steel 50 mm/min | TC 8 mm/min Steel 25 mm/min | TC 12 mm/min Steel 50 mm/min | TC 8 mm/min Steel 25 mm/min |

| aspect ratio d:L | 1:300 | 1:150 | 1:300 | 1:150 |

| operation | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox |

| IPC | Windows LTSC Enterprise | Windows LTSC Enterprise | Windows LTSC Enterprise | Windows LTSC Enterprise |

| options | - intermediate guide - rotary-tilt axis - dielectric fluid cooler - pneumatic quill | none | - intermediate guide - rotary-tilt axis - dielectric fluid cooler - pneumatic quill | none |

Product Brochure Download

machine accessories

collects, electrodes, dielectric oil etc.

answers and support for our machines

feel free to reach out with any inquiry.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.