technology and applications

Electroerosive drilling and Die sinking: on one machine

AGEMA EDM machines combine EDM drilling and sinker EDM in a single system, offering maximum flexibility to machine any conductive material, regardless of hardness

Fast EDM Drilling with Superior Precision

AGEMA EDM machines set new benchmarks in performance, enabling the machining of extremely hard materials such as tungsten carbide, hardened steel, polycrystalline diamond (PCD), and silicon carbide (SiC) at record speeds—up to 12 mm/min in carbide and 40 mm/min in steel. Even challenging materials like nickel alloys, tungsten, or titanium, which are difficult to process using conventional methods, can be machined efficiently and with exceptional quality.

Typical applications include:

- Start holes for tool and mold making

- Venting holes in injection molds

- Cooling holes in turbine blades for aerospace

- SiC parts for the semiconductor industry

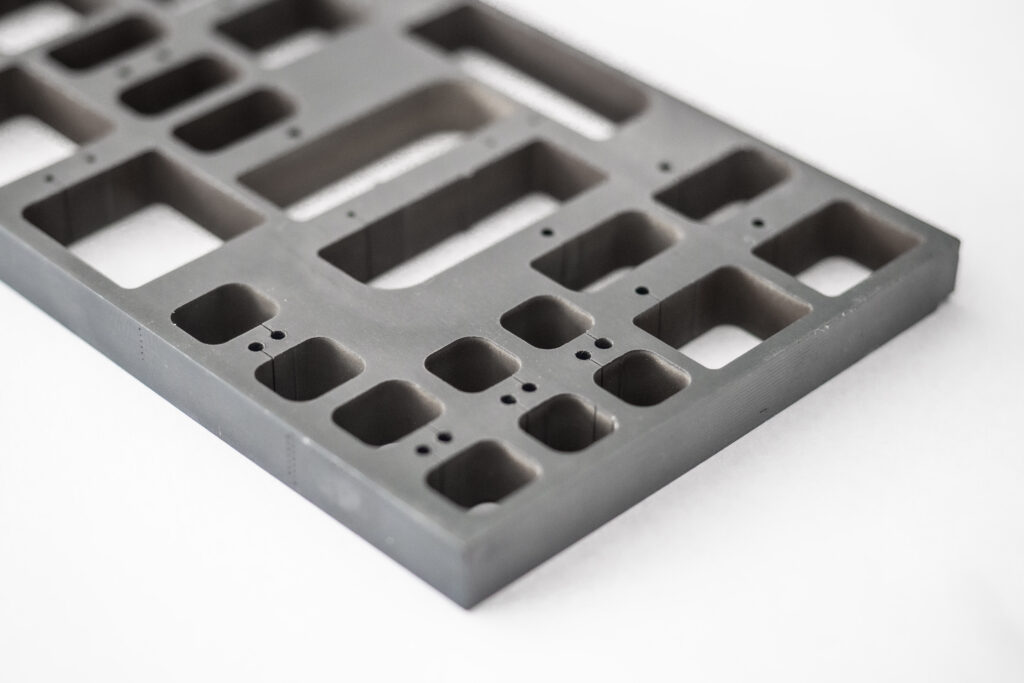

Image: Start holes in a 10 mm thick tungsten carbide plate.

Deep holes with high aspect ratio

On an AGEMA machine, the electrode is stabilized and guided by our high-precision intermediate guide, ensuring it remains perfectly straight even at extreme drilling depths. This enables deep precision holes with length-to-diameter ratios of up to 1:300, even for diameters below 2 mm—a capability that conventional deep-hole drilling machines simply cannot achieve.

Typical applications include:

- Holes for temperature sensors

- medical instruments

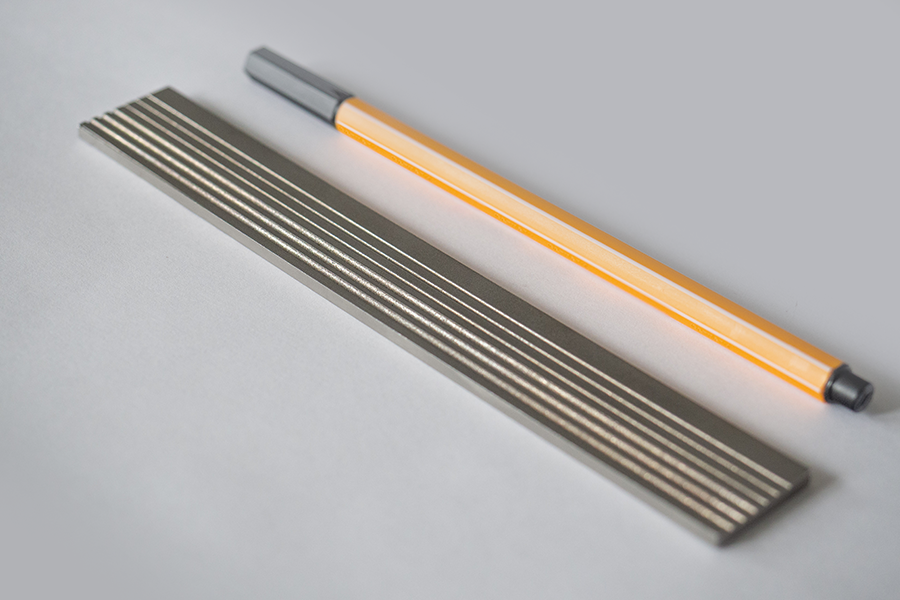

Image: 0.7 mm and 1.5 mm diameter holes drilled to a depth of 200 mm in stainless steel.

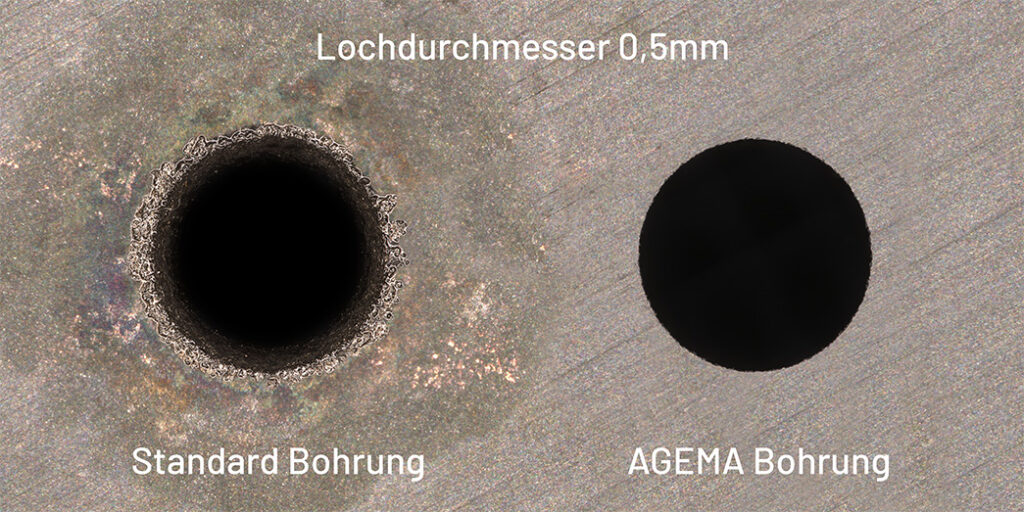

High surface finish

By using oil as the dielectric fluid, AGEMA machines achieve the highest precision and surface quality in EDM machining. This provides significant advantages for EDM processing and precision start-hole drilling of tungsten carbide:

- Minimal spark gap for tighter tolerances

- Superior surface finish

- No microcracks

- No corrosion

- No cobalt leaching

- Enables both sinking and drilling on a single machine

Image: water-based EDM machine vs. AGEMA oil-based EDM machine

Micro EDM Drilling – Ultra-Fine Holes

Delicate micro-holes starting from 0.06 mm in diameter are produced with full process reliability and repeatability – ideal for high-precision components in sensitive applications. AGEMA machines ensure outstanding accuracy and surface quality, even for the smallest diameters.

Typical applications include:

- Components for the semiconductor industry

- Medical instruments

- Precision nozzles for dosing and spraying systems

- Microfluidic components for analytical devices

- Watchmaking and fine mechanics

Image: 0.15 mm electrode in tungsten carbide with a drilling depth of 20 mm.

5-Axis EDM Drilling – Angled Holes

AGEMA machines feature a rotary-swivel axis, transforming the system into a full 5-axis EDM drilling machine. This enables drilling at virtually any angle, including very shallow entry angles, providing maximum design freedom for complex geometries. Ideal for applications where conventional drilling methods cannot deliver.

Typical applications include:

- Angled cooling channels in solid carbide cutting tools

- Oil and lubrication holes in forming and stamping tools

- Cross-holes in hydraulic and fuel injection components

- Venting holes in injection molds

- Cooling channels in turbine blades for aerospace

Image: Angled holes in a tungsten carbide blank.

EDM drilling thin-walled components

Because EDM drilling is a contactless process, it is perfect for thin-walled or delicate components without risking deformation or damage. This makes it the ideal solution for high-precision parts in demanding industries.

Typical applications include:

- Nozzles and evaporators in aerospace and energy sectors

- Cooling holes in turbine blades

- Thin-walled tubes for medical instruments

- Heat exchanger components

- Precision parts for microfluidic systems

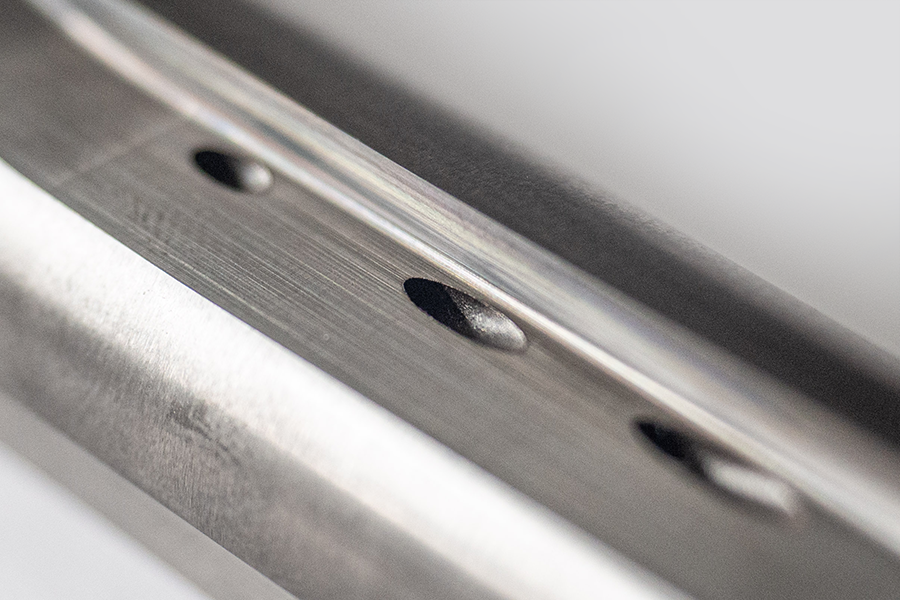

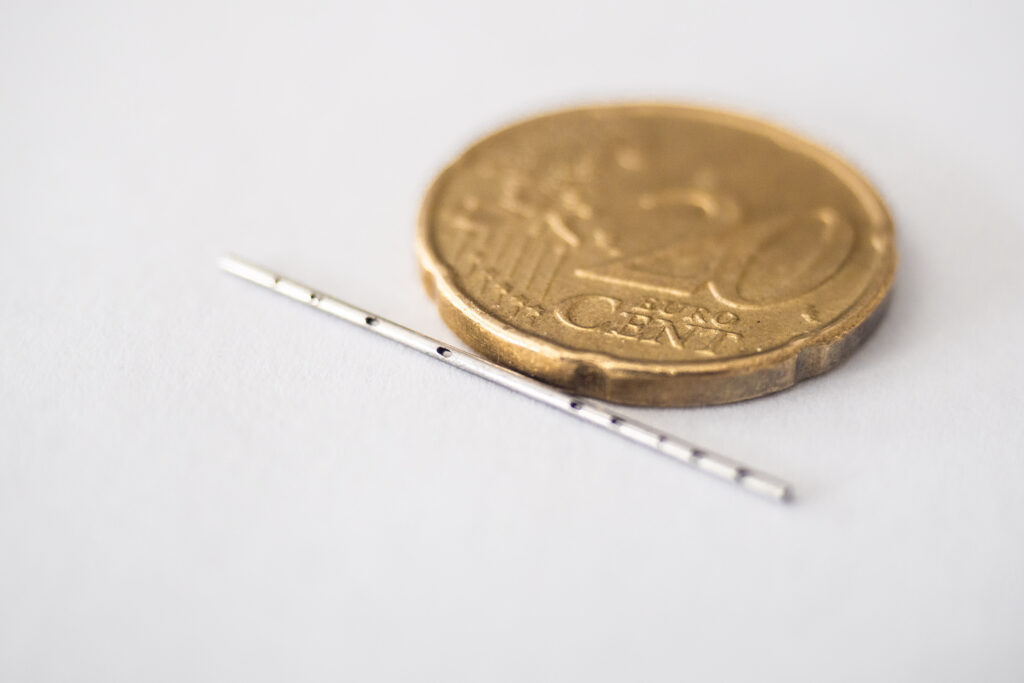

Image: Stainless steel tube with 0.1 mm wall thickness featuring EDM-milled slots measuring 0.2 × 0.4 mm.

EDM Drilling and Sinking on One Machine

AGEMA machines combine fast hole EDM drilling with die-sinking EDM in a single system. This unique capability allows not only drilling but also creating threads, countersinks, and precision fits directly on the same machine. Existing holes can be enlarged to achieve exact diameters, offering maximum flexibility for complex components in hard materials like tungsten carbide and hardened steel.

Typical applications include:

- Functional holes in titanium components for aerospace

- Threaded holes and precision fits in carbide and hardened steel molds

- Enlarging and finishing holes for exact tolerances

- Complex geometries requiring both drilling and sinking operations

Image: Tungsten carbide block with threaded holes from M3 to M8.