AGEMA Classic: The cost-optimized start hole EDM machine

The AGEMA Classic series is our specially designed, cost-optimized small hole EDM machine, perfectly suited for start hole drilling and simple sinking operations. As the smaller sister of our high-end models, it offers proven technology at an attractive price—without major compromises in performance and quality. Developed and built in Germany, with spare parts available for decades.

High performance thanks to AGEMA generator

The heart of the AGEMA Classic is the newly developed pulse generator from our high-end series. It combines more than 30 years of in-house expertise with state-of-the-art power electronics, giving this affordable entry-level model almost all the power of the premium models.

High speed start hole EDM

When performing small hole EDM drilling—also known as start hole drilling in toolmaking—it’s not the last few microns of precision that matter, but pure speed and reliability. The AGEMA Classic EDM drilling machine delivers exactly that: exceptional performance, especially when drilling in carbide

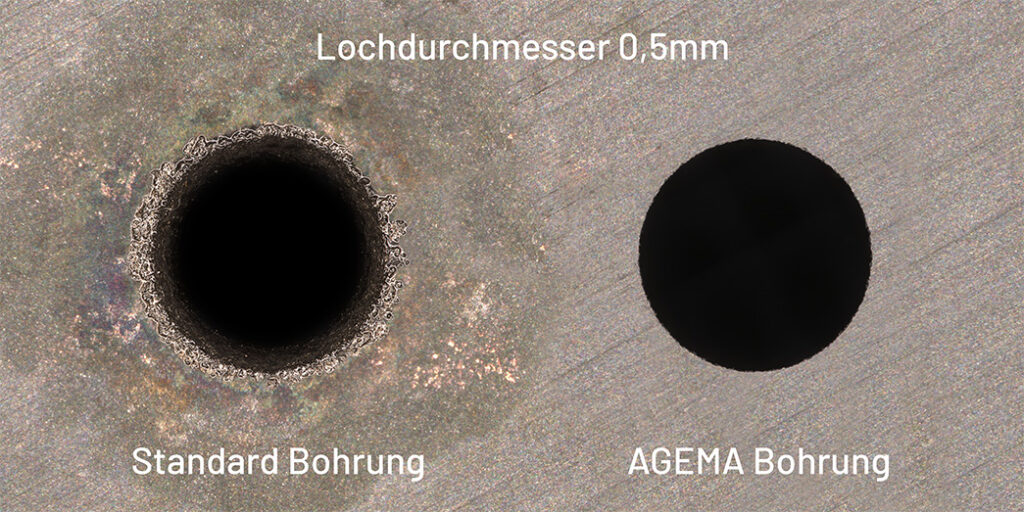

CYLINDRICAL HOLES

Cylindrical holes are required for good breakthrough behavior and optimal core hole drilling during thread erosion. We have developed parameters specifically for this application that control electrode wear in such a way that the electrode wears down as cylindrically as possible.

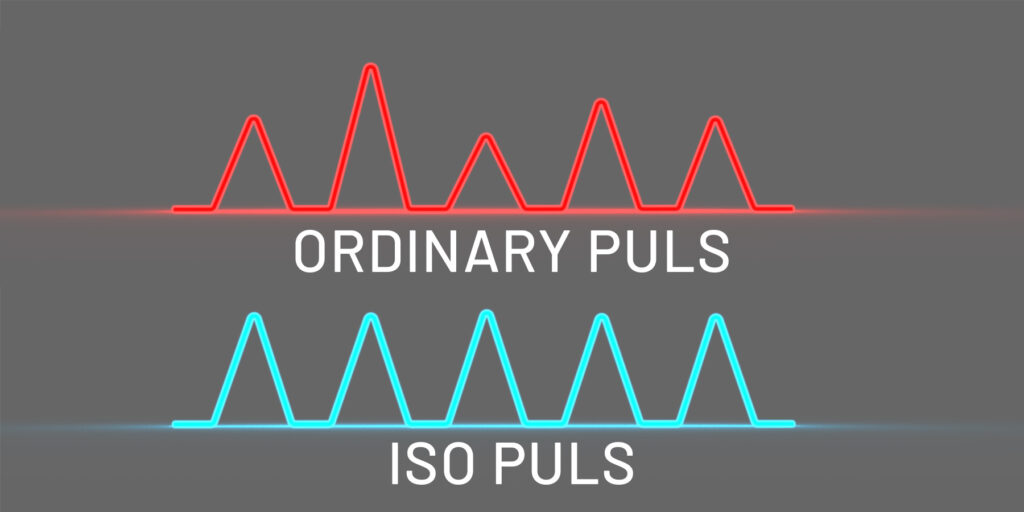

minimal electrode wear

Each individual discharge is precisely controlled so that every discharge releases the same amount of energy. This minimizes electrode wear and improves surface roughness.

excellent surface quality

Thanks to precisely controlled processes and the oil dielectric, the material structure is hardly damaged at all—free of microcracks or splashes.

energy efficient

The generator’s state-of-the-art and efficient circuit design, an intelligent sleep mode when not in use, and an innovative high-pressure system significantly reduce energy consumption. This greatly reduces the waste heat emitted into the dielectric and the environment.

Minimal downtime

In the event of a generator failure, it can be replaced directly with a new generator on site. This means that machine downtime is kept to a minimum, as there is no need for time-consuming maintenance work on the machine. In other words: you continue production at your site, while we carry out repairs at ours.

Flexible start hole EDM machine with simple operation

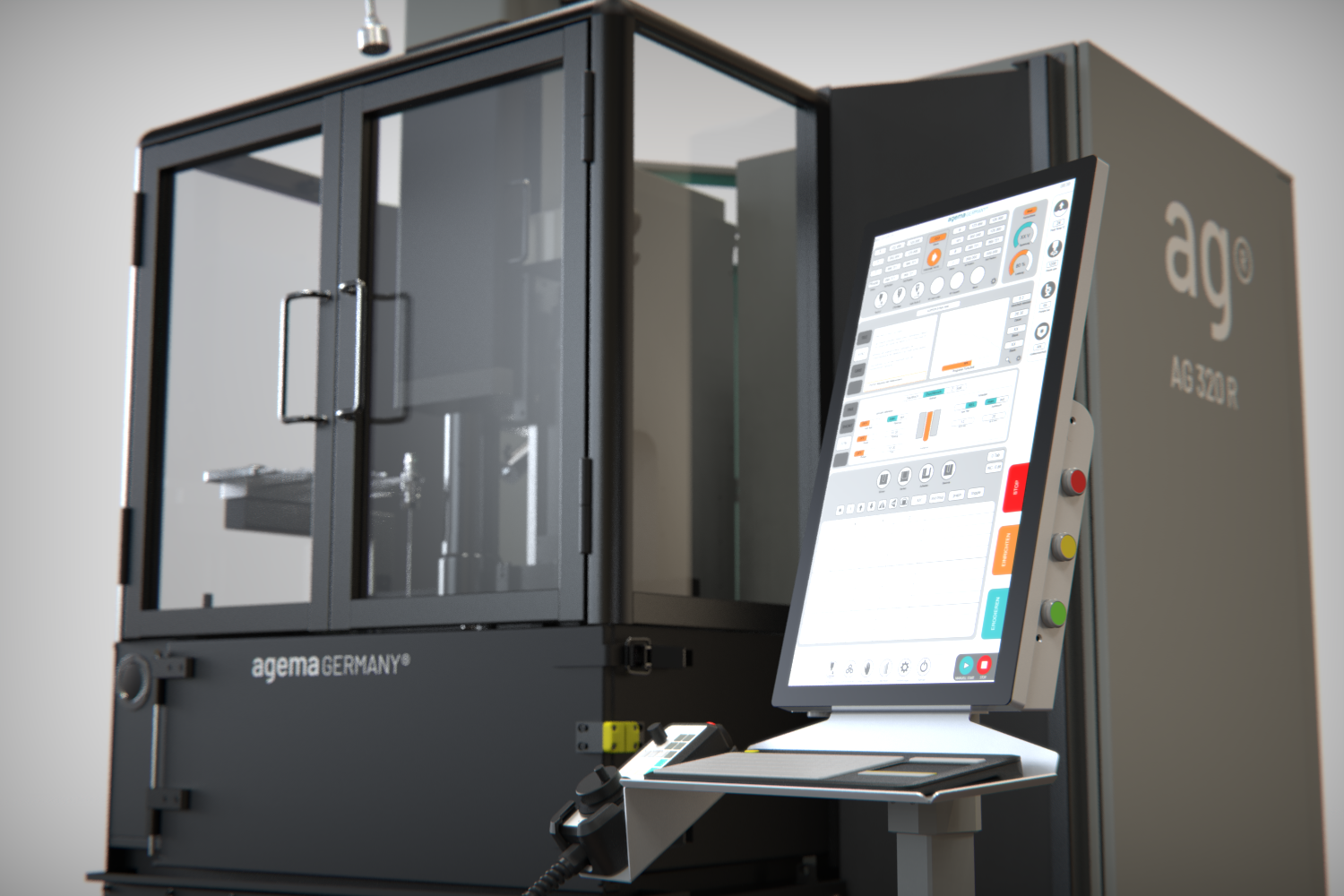

Modern, intuitive control

Windows-based, user-friendly, and optimized for daily use—just like the premium machines.

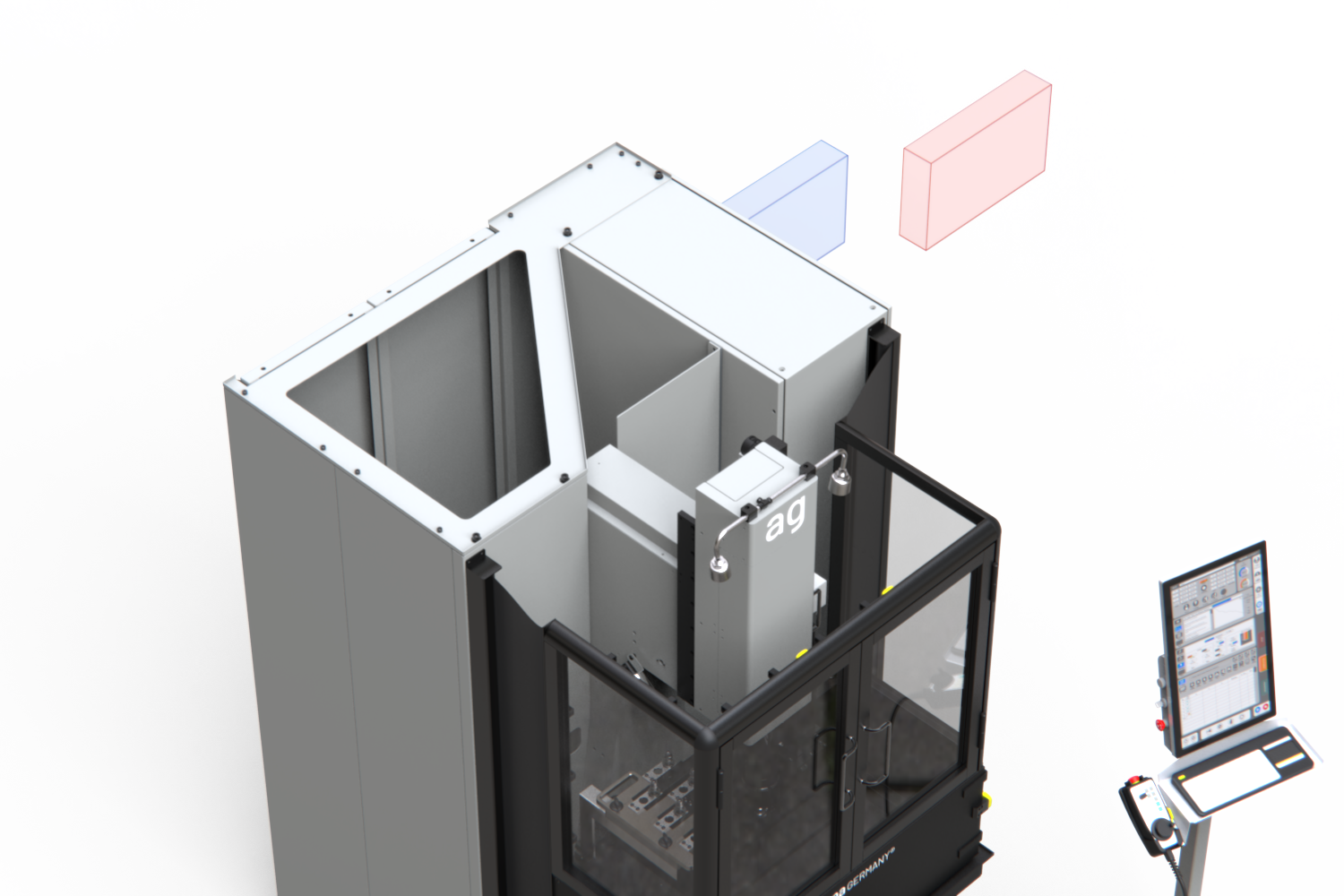

Quick changeover to die-sinking EDM

Conversion in a matter of seconds by removing the arm with the electrode guide. Ideal for threads in carbide, hardened steels, or other materials—without additional machines.

Focused on the essentials

No automated electrode changer, no pneumatic quill, no glass scales, no 5-axis machining, and no intermediate guide. This reduces costs and increases robustness.

Premium models AG 320 and AG 430

Do your requirements go beyond standard drilling?

Discover our premium series—with the latest developments and features for maximum precision!

machine specifications

| Parameter | AG 320 | AG 320 Classic | AG 430 | AG 430 Classic |

|---|---|---|---|---|

| traverse path XY | 300 × 200 mm | 300 × 200 mm | 400 × 300 mm | 400 × 300 mm |

| electrode stroke | 280 mm | 280 mm | 400 mm | 400 mm |

| max. workpiece height | 240 mm | 240 mm | 300 mm | 300 mm |

| basin | 800 × 500 × 260 mm | 800 × 500 × 260 mm | 1050 × 650 × 320 mm | 1050 × 650 × 320 mm |

| electrode diameter | 0,05 – 10 mm | 0,2 – 10 mm | 0,05 – 10 mm | 0,2 – 10 mm |

| positioning accuracy | 0,002 mm | 0,02 mm | 0,002 mm | 0,02 mm |

| max. flushing pressure | 140 bar | 80 bar | 140 bar | 80 bar |

| max. workpiece weight | 200 kg | 200 kg | 200 kg | 200 kg |

max. electrode weight | 5 kg | 5 kg | 5 kg | 5 kg |

| machine weight | 1600 kg | 1600 kg | 1900 kg | 1900 kg |

| electrode changer | 6 fold | No | 8 / 40 fold | No |

| guide changer | No | No | Yes | No |

| generator performance | 50 A | 40 A | 50 A | 40 A |

| max. drilling performance | TC 12 mm/min Steel 50 mm/min | TC 8 mm/min Steel 25 mm/min | TC 12 mm/min Steel 50 mm/min | TC 8 mm/min Steel 25 mm/min |

| aspect ratio d:L | 1:300 | 1:150 | 1:300 | 1:150 |

| operation | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox | 22” Touch + Keyboard + Handbox |

| IPC | Windows LTSC Enterprise | Windows LTSC Enterprise | Windows LTSC Enterprise | Windows LTSC Enterprise |

| options | - intermediate guide - rotary-tilt axis - dielectric fluid cooler - pneumatic quill | none | - intermediate guide - rotary-tilt axis - dielectric fluid cooler - pneumatic quill | none |