EDM Fast Hole Drilling Machine AGEMA

AS 430

Small Hole Drilling & EDM Threading on one EDM Fast Hole Drilling Machine AGEMA

AS 430

Small Hole Drilling & EDM Threading on one EDM Fast Hole Drilling Machine AGEMA

Reproducable small hole drilling

≤ 0,3 mm into different materials such as carbide or steel.

Examples of use with EDM Fast Hole Drilling Machine AGEMA.

Predefined technology parameter for carbide and steel:

Find out everything about the AGEMA technologies and machines – all made in Germany.

AGEMA enables a high surface quality & minimal damage of the material.

More about it here with the eroding results.

- Clamping area: 650 x 400 mm

- Workpiece weight max.: 300 kg

- Workpiece dimensions max.: 1000 x 600 mm

- Range of traverse X, Y: 400 x 300 mm

- Continious eroding hub Z: 400 mm

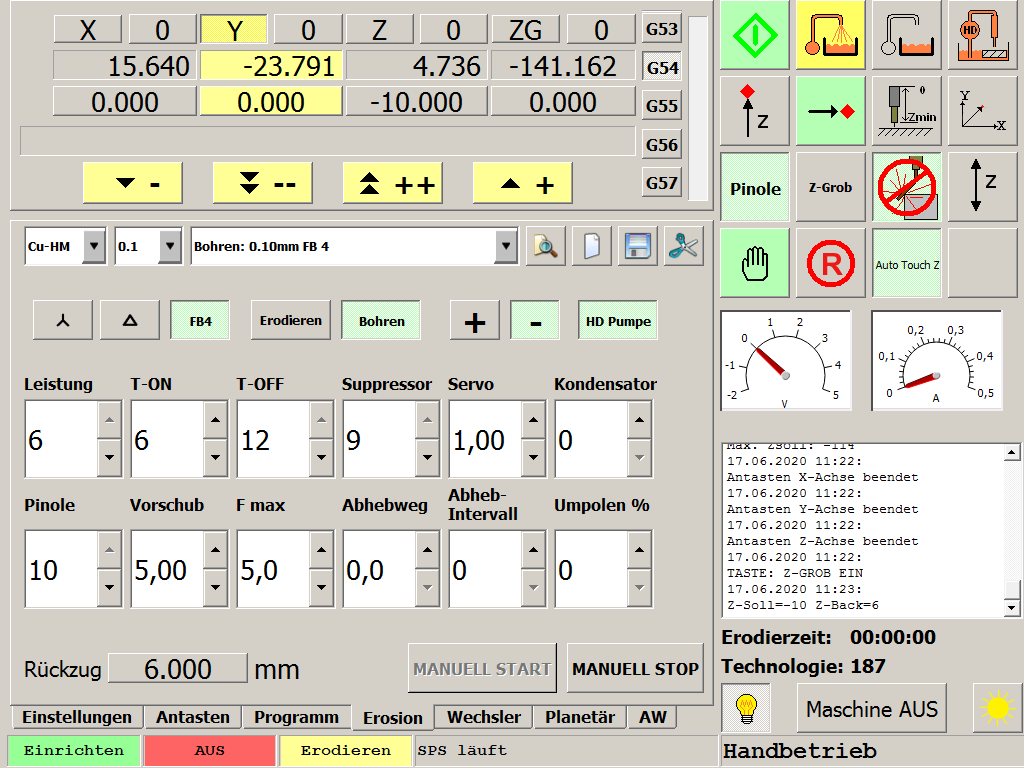

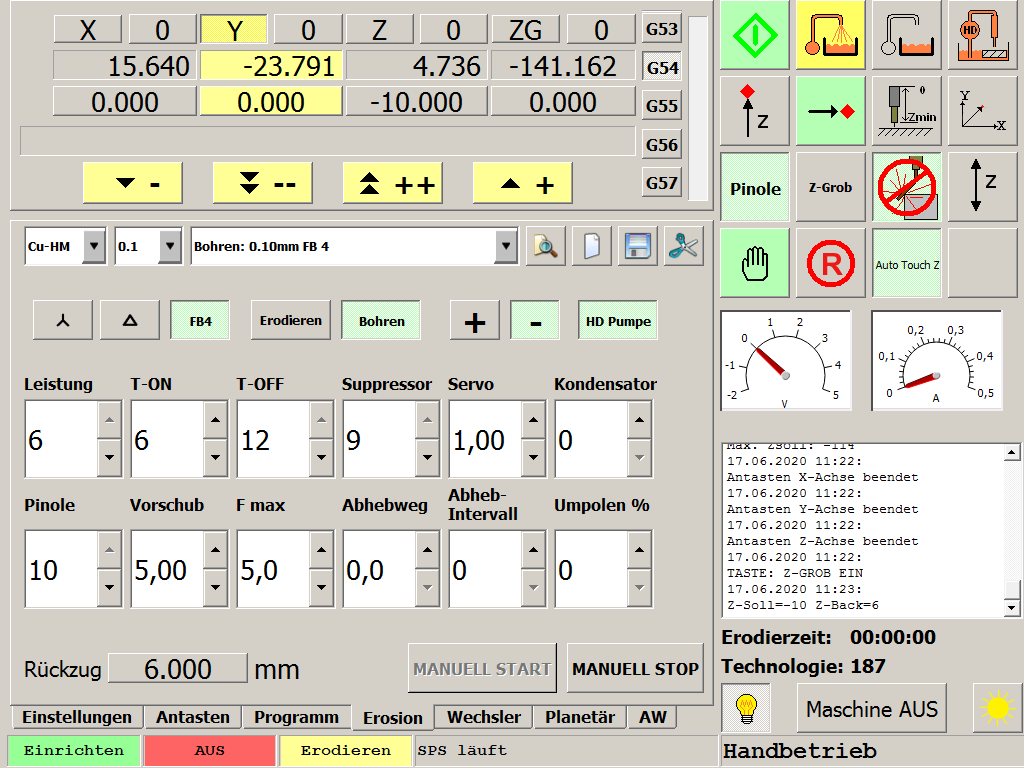

CNC Control & Generator of AS 430

Connectivity & intuitive operability of AGEMA EDM Start Hole Drilling Machine

Special Features of the CNC Control & the Pulse Generator

The performance of CNC machines depends particularly on their control. Hence we have made decisive improvements to the control of the AGEMA EDM machine and placed great emphasis on functionality and simple & easy operability. With the control based on Windows 10 we can make individual adjustments.

BREAKTROUGH DETECTION

Automatic detection and completion of the drilling

ORBIT

Moving the electrode on paths (e.g. circular orbit for threads)

PREDEFINED

standard technologies enable the processing of all conductive materials

AUTOMATION

OPC-UA for integration into automated production environments

COLLISION PROTECTION

Prevents total machine damage in case of user error

REMOTE SERVICE

remote access enables quick diagnostics and immediate help

NETWORK CONNECTIVITY

Integration into the local network or internet via LAN, WLAN or LTE

MONITORING

process monitoring with meaningful graphs and diagrams

BREAKTHROUGH DETECTION

Automatic detection and completion of the drilling

COLLISION PROTECTION

Prevents total machine damage in case of user error

PREDEFINED

standard technologies enable the processing of all conductive materials

MONITORING

process monitoring with meaningful graphs and diagrams

AUTOMATION

OPC-UA for integration into automated production environments

REMOTE SERVICE

remote access enables quick diagnostics and immediate help

ORBIT

Moving the electrode on paths (e.g. circular orbit for threads)

NETWORK CONNECTIVITY

Integration into the local network or internet via LAN, WLAN or LTE