EDM Precisiondrilling

and Small Hole Drilling in Carbide

Examples of use

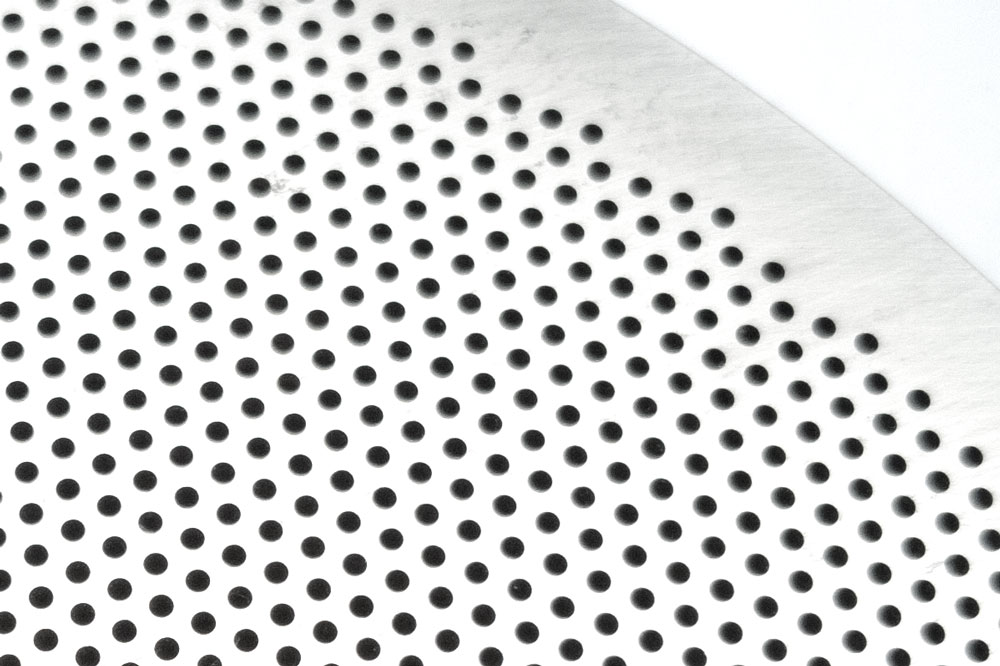

Small Hole Drillings

Small Hole Drilling on the AGEMA machine is extremely reliable.

Compared to carbide electrodes, low-cost copper electrodes are used.

Small Hole Drilling is characterized by very low electrode wear. The special generator technology allows a very small spark gap.

This means that holes with a final diameter of 0.15 mm can be produced using 0.12 mm electrodes

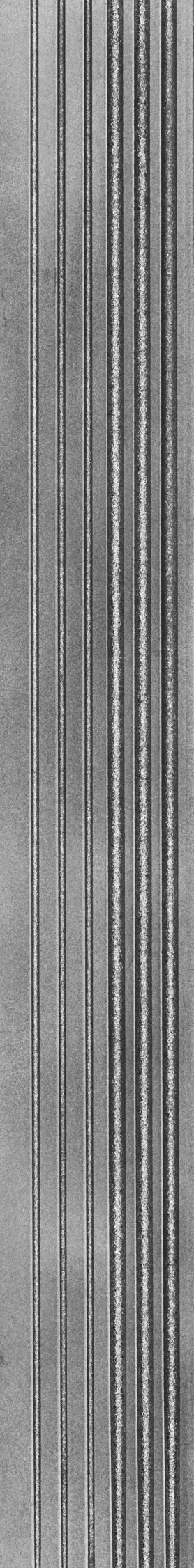

Small Hole Drillings:

Electrode diameter 0,2 mm

– in carbide

– Drilling depth 30 mm

The trend towards miniaturization requires ever smaller and deeper hole drillings.

Thanks to decades of development, deep hole drillings and small hole drillings can be drilled with AGEMA machines with high process reliability, speed and precision.

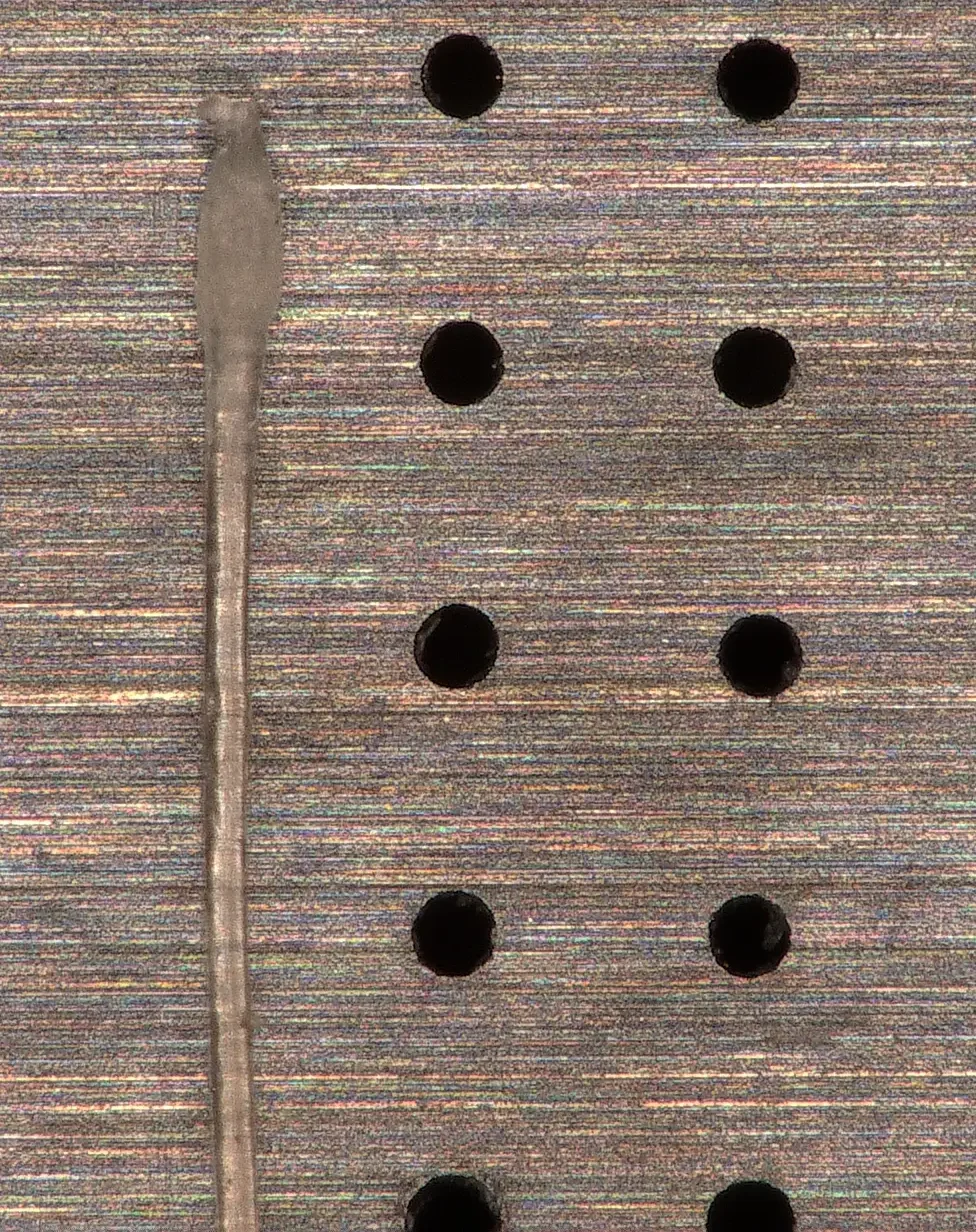

Deep drillings

Deep – deeper – AGEMA

The Key to depth

Our high-precision intermediate guide stabilizes and guides the electrode in such a way that it does not run, even at great drilling depths.

More information about the intermediate guide or small hole drilling you can finde here.

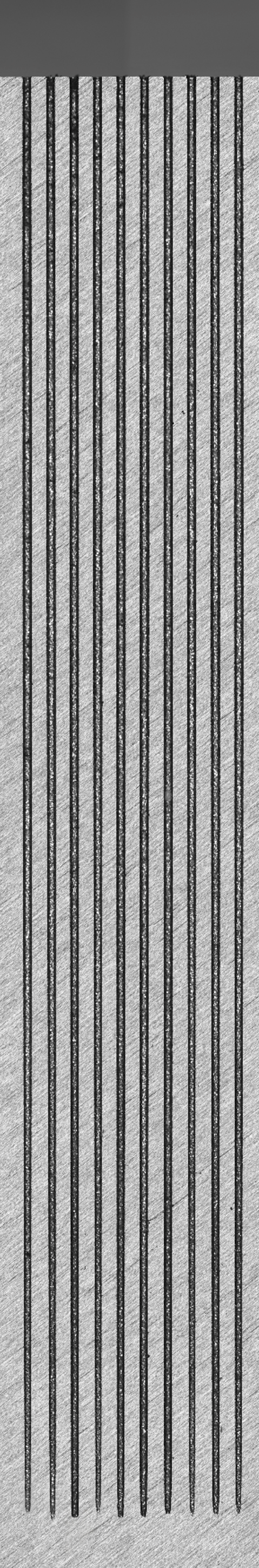

Bohrtiefe: 200 mm

Material: Edelstahl

Elektrodendurchmesser:

0,70 & 1,50 mm

Bohrtiefe: 60 mm

Material: Stahl

Elektrodendurchmesser:

0,30 mm

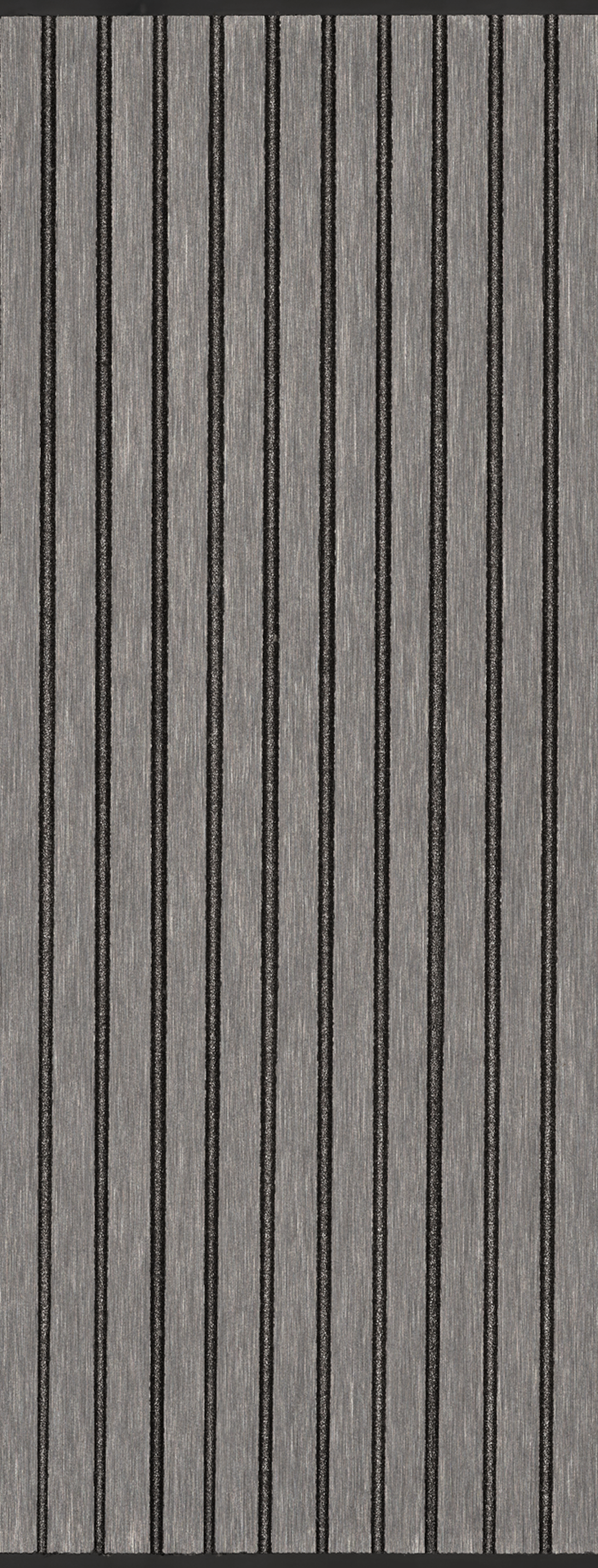

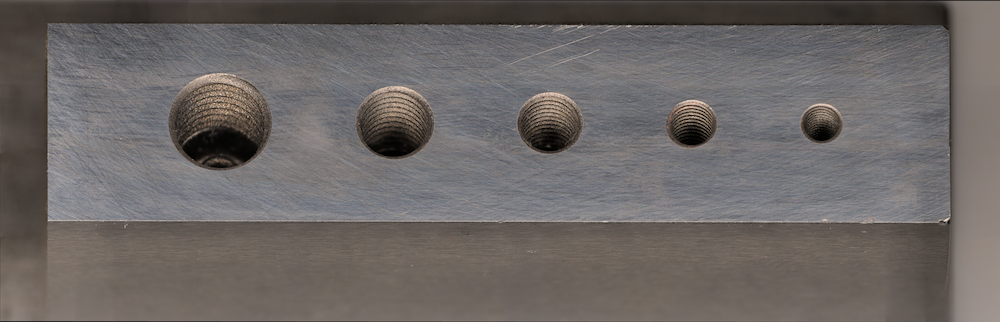

Threads into Carbide – Sinker EDM

Insert Threads into Carbide

Our special area are EDM machines for erosive fast hole EDM drilling and sinker EDM in carbide and hardened steel on one machine.

Furthermore, drillings can also be widened and thus high-precision diameters can be produced.

M2 M6 threads in carbide are shown here on the picture.

Fast Hole EDM drilling

Fast hole EDM drilling for precision stamped parts

Electronics, e.g. plugs

During fast hole drilling on the AGEMA machine, microcracks are reduced to a minimum. For this purpose, we use special erosion technologies and erode with oil as dielectric.

Find the right AGEMA machine that suits to your requirements.

Small Hole Drilling and Precisiondrilling

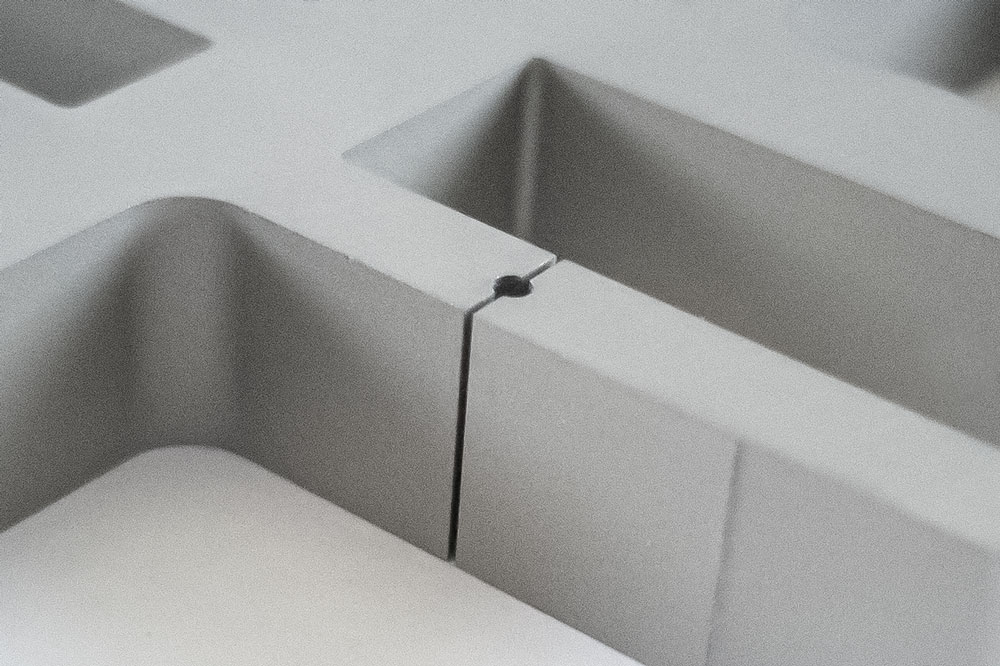

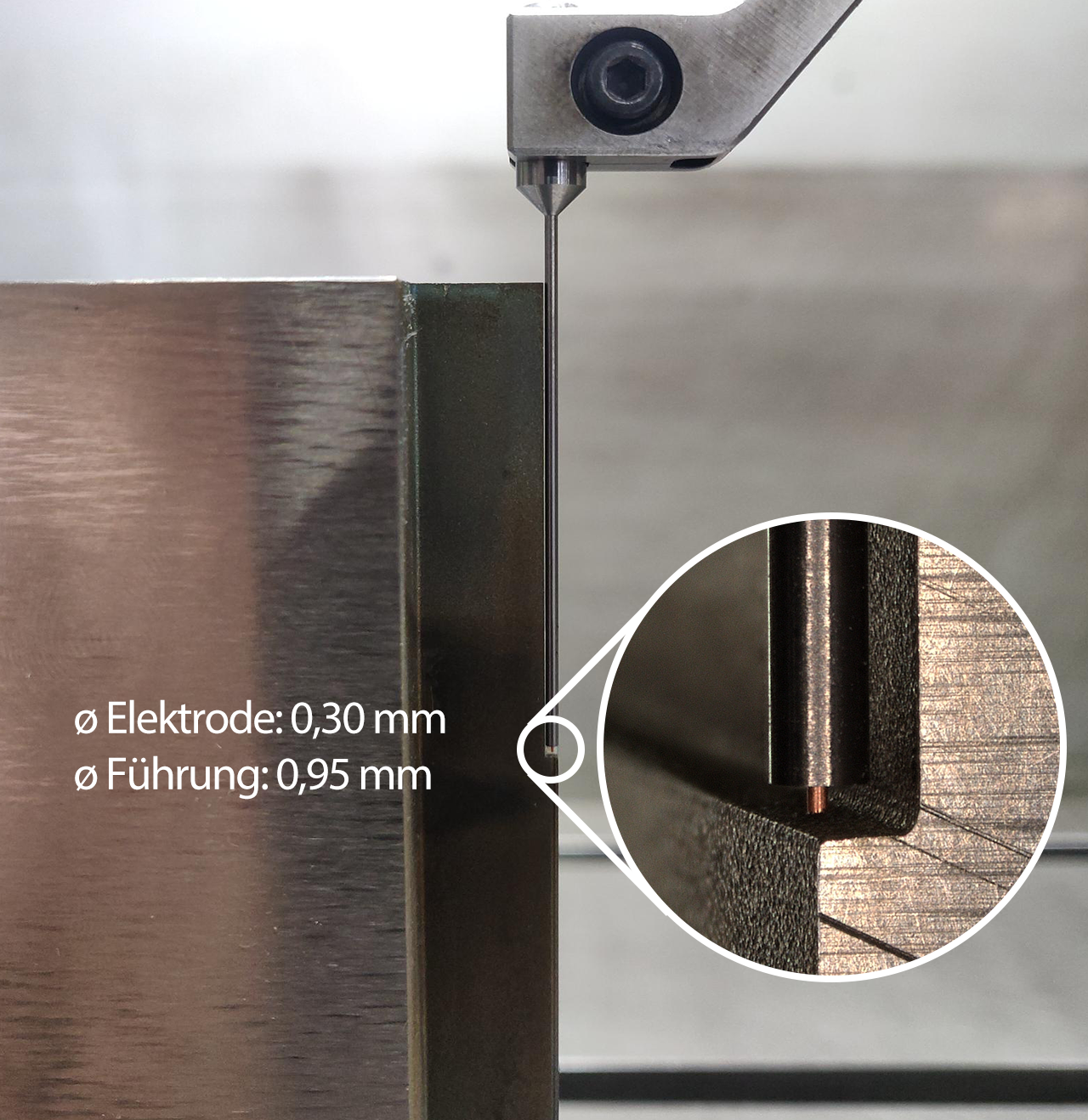

Special guide for precisiondrilling

With our special guide, small holes drillings can be positioned very precisely in hard-to-reach places.

We manufacture the guides according to customer requirements. With the guide shown can be used to drill holes at a depth of up to 45 mm.

Electrode changer

With our electrode changer even small hole drillings can be changed reliably.

It enables unmanned operation for hours.

More information you will find here.