Hole drilling EDM & Sinker EDM

Two Technologies – One Machine

![]()

Hole Drilling EDM

![]()

Sinker EDM

The AGEMA Start Hole Drilling Machines combine both technologies, the erosive hole drilling EDM and sinker EDM, on one machine.

The AGEMA Start Hole Drilling Machines combine both technologies, the erosive hole drilling and sinker EDM, on one machine.

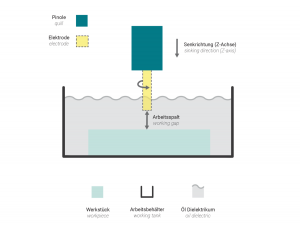

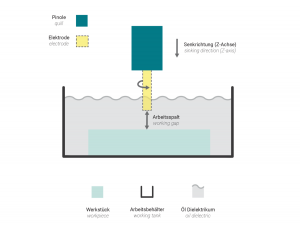

Electrical Discharges during Hole Drilling EDM & Sinker EDM

Our AGEMA EDM Start Hole Drilling Machines use electrical discharges to achieve a thermal abrasion on the workpiece surface without damaging the micro structure.

Electrical discharges

Our AGEMA EDM Machines use electrical discharges to achieve a thermal abrasion on the workpiece surface without damaging the micro structure.

Please leave your contact details and we are happy to send you example videos.

Hole Drilling EDM

Erode high-precision holes with an AGEMA EDM Start Hole Drilling Machine.

Start holes: electrode diameters from 0.30 up to 10.00 mm

Small hole EDM drilling: electrode diameters from 0.08 up to 0.30 mm

Deep hole drilling: very high aspect ratios of up to 1:300 even at small diameters

Angeled drillings: any angle from 0° to 180° relative to the workpiece axis

Precision drill holes in steel and carbide with a proven minimal damage of the material

High accuracy of the drill holes (position, straightness, cylindricity)

Fast Hole EDM drilling: High ablation rates, especially in small diameters

Sinker EDM

AGEMA Machines are also suitable to perform sinker EDM applications

Fits

EDM Tapping: EDM Threading in carbide and any other conductive materials using predefined technologies

Realization of small die sinking EDM jobs

Realization of different levels of roughness when die sinking

Functional Sketch about Enlargening with Hole Drilling EDM & Sinker EDM

More details about the AGEMA EDM Start Hole Drilling Machines:

Hole Drilling & Die Sinking:

The workpiece materials

The AGEMA EDM Start Hole Drilling Machines can process all electrically conductive materials:

Carbide

Coated materials

particularly gentle processing of e.g. PCD, CBN, TiAlN

Brass

Nickel-based alloys

Steel

powder metallurgical steels, cold & hot work steels

Conductive ceramic

Aluminium

Copper

Titanium